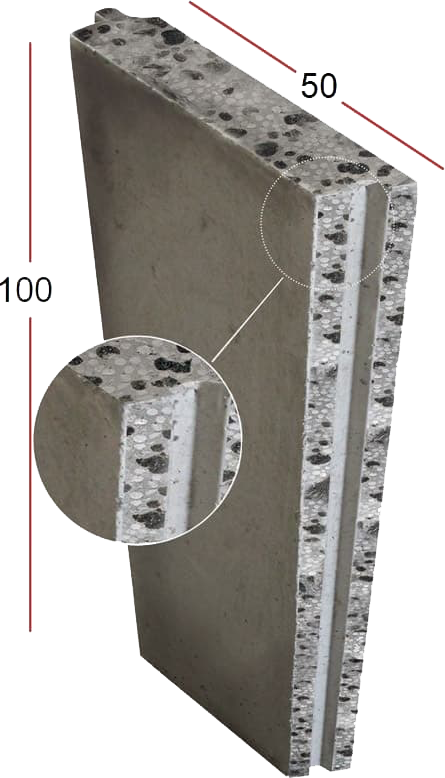

Ultra-Lightweight Concrete Wall Panel

Ultra-Lightweight Concrete Wall Panel

Specifications

As we need to lighten and improve the performance of the building against earthquakes and also increase the speed of execution and more efficient productivity of manpower in construction workshops, making new materials with new methods and machinery, is among the necessities of engineering and construction management. One of these new methods is the invention, design and making of a kind of wall concrete panel with ultra-lightweight concrete technology with high strength by me, which can be one of the best-selling and most important products in the construction industry. These panels can be used in surrounding walls and interior partitions. In addition, their easy transportation with high installation speed has considerably reduced the time and execution costs. The designed ultra-lightweight concrete panels have national and international patents and approvals. The special capabilities of this high-quality product, which leads to a reduction in execution costs, are of attention of constructors of private and public buildings and even special.

Advantages

- Very low weight of the product: The weight of each m² of this panel for the interior wall with the thickness of 7 cm is equal to 35 kg. The use of these wall panels significantly reduces the dead load of the building, because the most important way to prevent damage and loss caused by earthquakes is to reduce the weight of the structure and one of the most important methods of lightening the structure is to reduce the weight of the walls, which will be achieved by using lightweight panel in the surrounding and interior walls.

- Increasing the execution speed: Considering the large dimensions of this product and its low weight, in addition to reducing manpower and time to transport the product and its special mortar to the floors (compared to the traditional type of mortars and materials, while a few of these lightweight materials easily create a complete wall and there is no need to transport heavy materials such as sand and cement in comparison with transitional method)

- Easy Execution: It is very easy to transport and carry these panels due to their low specific weight and lightweight.

- Reduction of execution costs: Due to increased speed and easy execution (reduction of manpower, reduction of time for using manpower, reduction of time for using of lifting devices, reduction of manpower during execution of project as a result of using use of this product and its special mortar and lack of the need to transfer sand by spending a lot of time and money to make mortar, reducing the cost of materials waste, reducing the cost of moving material).

- Reduction of construction cost: Due to the reduction of dead loads on the building and the possibility of saving in the structure of building (according to the existing regulations in the national regulations of building, by reducing the dead load on the building, the amount of rebar and concrete used in the structure will be decreased and we will have a structure which is more resistant against earthquake).

- Reduction in the amount of mortar because of using the standard seams between the product.

- Possibility to eliminate the gypsum and soil under the plastering layer and the possibility of plastering independently.

- Possibility of using different coatings on this surface, including plastering, ceramics or gypsum sheets.

- Possibility of installing screws and bearing the weight of kitchen cabinets and… .

- These panels are resistant against moisture and you will see no destruction in comparison with lightweight gypsum panels (this product can be used in wet spaces such as bathrooms and toilets)

- Possible to cut some part of the product to pass water and electricity pipes without destroying the wall due to the integrity and type of concrete used in the product (in case of using traditional materials such as blocks and clay sheets, material waste will remain in the site after cutting).

- Possible to manually cut the panels or use a milling machine; however, the cutting operation is very easy and is also possible with a saw.

- Proper sound insulation due to using materials with good porosity.

- Heat insulation (due to the heat-resistant polymer materials used in these panels, they slowly transfer heat to the adjacent space).

- It is possible to use these panels in special projects with high coefficient of importance such as clinics and hospitals with special details.

- Low thickness along with the insulation property of the product, has resulting in more appropriate using of the space and less occupation of the area of the building by the wall.

- Resistance of the product against lateral forces, especially during earthquakes, and creating a more integrated surface and no cracks in the product considering the specific type of concrete.

- Providing a clean place with no splashing or waste of traditional mortar due to using the special mortar (special adhesive).

- It is possible to combine these panels with different execution methods and different types of structures with different applications.

- Proper for all regions and climates, even humid climates.

- No materials, which are harmful for human health, are uses in these panels.

- The product is resistance against fire because of using suitable cementitious materials and minerals.

- It is possible to use different types of wall pastes, especially their light types and reduce the amount of iron used in the building.

- Considering the big size of this product, the waste of materials is less and cut materials can be used under the window and on the top of the walls with similar sizes and regular dimensions.

- High durability of product.

- The product has high mechanical strength such as high bending and compressive strength.

- Mortice and tenon joint is used in vertical joints to firmly connect the parts together, while the mortice and tenon joint in horizontal joints has been eliminated due to inefficiency and the special mortar is used to firmly connect the parts together (it is possible to use rebar in the horizontal joints of the product).

- Possible to store the material in construction workshop because they need smaller spaces in comparison with conventional cement blocks.

- Possible to creating a completely hygienic environment in the wall and there will be no negative space and empty space between the walls

No : 32M / 28239

Patent statement No : 38710025

Invention Registration No : 55679

Click to See More Details About This Invention

Owner and Inventor

Inventor

Mr. Davoud Beheshtizadeh

Click to Download Davoud Beheshtizadeh's CV

High-Performance, Flexible Fiber-Reinforced Concrete New Jersey Barrier

Invention Summary

High-Performance, Flexible Fiber-Reinforced Concrete New Jersey Barrier with the Property of Absorbing the Energy from Crash to Protect Human Lives and Reduce Financial Losses during the Crash

New Jersey is a type of concrete barrier that is made at different heights such as one, two, and three meters and is used in highways in order to prevent detours and violations by drivers for providing security and preventing crashes, and entry and exit in some cases and controlling the traffic and preventing from annoying headlights of cars on the opposite side. Concrete New Jersey barriers are made of prefabricated concrete parts that can be connected together to direct the vehicles and put them in the route when crashing with the side of the vehicle that acts as a reversing guide due to the low angle of its edges and reduces the damages. It is also used to protect the pedestrians, protect the construction workers from vehicles, act as temporary barriers and anti-terrorist security barriers, as well as flood barriers, prevent forest fires, direct the river and create several lanes in the roads. This invention is the design and construction of a new generation of highway concrete in New Jersey that will significantly prevent financial and casualties due to traffic crashes. This special type of New Jersey is made as a hollow shell of high-performance and high-strength fiber concretes using nanotechnology, which is filled with shock-absorbing earth materials, and at the same time, its high resistance acts as an energy dump in the event of a crash and reduces the effect of the impact and directs the vehicle in its route. This performance of New Jersey reduces the risk of casualties and deaths during the crashes.

The flexibility and the ability to create a joint in the event of a crash is one of the efficiencies of New Jersey, and its function during the crash is to absorb the energy of impact and reduce its effects. This product has been successfully produced after several months of laboratory studies, software analysis, field tests, and workshops tests and is can be presented in different facings.

Description of Appearance

Hollow concrete modular parts are made of resistant concrete and strong fibers, the edges of which are curved with a slight angle and are made with the height of 100 cm and the standard length of 400cm and 600cm. This shell is filled with soft soil or earth materials (without rubbles) in order to increase the weight and also increase the softness and flexibility for absorbing the energy of impact. This New Jersey barrier has lateral fittings in order to be installed on longitudinal guardrails.

Patent Application Number: IR 14004000300545

Click to See More Details About This Invention

Team Members of This Project

Some of Awards and Honors

- International Invention Innovation Competition in Canada, iCAN 2019 and 2021 – Toronto, Canada / Gold Medal and Special Award of Toronto International Society of Innovation and Advanced Skills (TISIAS)

Gold medal at America’s Largest Invention Show “INPEX 2016 and 2017”, The Invention and New Product Exposition

Gold Medal in Civil Engineering Category at the Geneva Inventions Exhibition 2016 and 2017

Gold Medal in Nuremberg International Invention Fair “iENA 2015 and 2016

Gold Medal at the 57th Edition the World Exhibition on Innovation Research and New Technology “EUREKA 2008” Belgium

Gold Medal at the 20th International Invention, Innovation and Technology Exhibition “ITEX 2009” Malaysia

Holder of 18 State Awards At reputable national Olympiad and Competitions in the Field of concrete